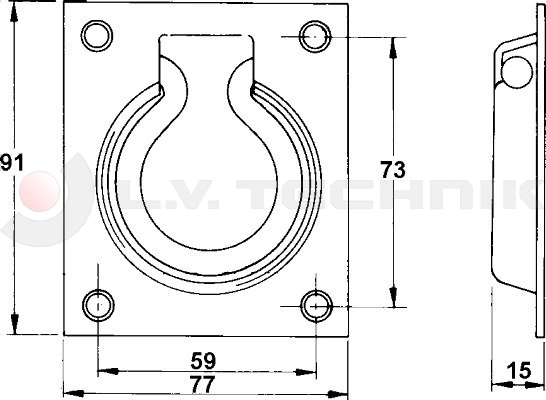

Lashing ring 76x90mm

- Suitable for the requirements of the ISO 27956

Regulations and norms

Based on the type of the vehicle lashing points must meet the requirements of different rules and regulations. The table below gives a quick overview about the required lashing capacities (LC) of lashing points according to different regulations.

| vehicle type, regulation | max. mass (t) | min. lashing capacity (LC) | note |

|---|---|---|---|

| passenger car ISO 27955 |

- | 350 daN | |

| van ISO 27956 |

up to 2.5 tons | 300 daN - 400daN | based on Fp/2 formula* |

| between 2.5 - 5 tons | 350 daN - 500 daN | based on Fp/3 formula* | |

| between 5 - 7.5 tons | 350 daN - 800 daN | baes on Fp/4 formula* | |

| dropside truck, trailerDIN 75410-1 | up to 3.5 tons | 400 daN | |

| truck, trailer EN 12640 |

between 3.5 - 7.5 tons | 800 daN | |

| between 7.5 - 12 tons | 1000 daN | ||

| above 12 tons | 2000 daN | ||

| above 3.5 tons | 1000 daN | lashing point built in the headboard | |

| *: Fp is the payload given in daN; the minimal lashing capacity of a lashing point is calculated by the given formula | |||

Also the capacity of the lashing device (lashing strap, chain etc...) must taken into consideration and increase the lashing point capacities based on the table bellow if needed.

| lashing device | lashing point capacity |

|---|---|

| lashing strap with at least LC 2000 daN | 2000 daN |

| lashing strap with at least LC 2500 daN | 2500 daN |

| 8mm lashing chain | 3000 daN |

| 10mm lashing chain | 5000 daN |

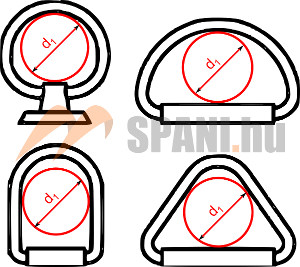

There are also some size requirements to quarantee the applicability of different lashing device hooks.

| d1 (mm) | max. mass (t) |

|---|---|

| 40 or 25x40mm | EN 12640, DIN 75410-1 |

| 35 | between 5 - 7.5 tons ISO 27956 |

| 25 | between 2.5 - 5 tons ISO 27956 |

| 20 | up to 2.5 tons ISO 27956 |

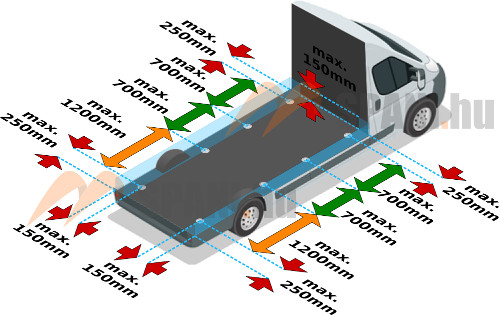

Lashing point placement in case of vans (ISO 27956)

- Lashing points must be placed on the platform or sideboards not higher than 150mm.

- Distance from the sidewalls must be as small as possible and cannot be more than 150mm.

- Lashing points must be placed in pairs, equaly distributed.

- Lashing points must be placed within 250mm of the front part and the rear part of the platform.

- Platforms not longer than 1300mm must have at least 4 lashing points (2 on each side).

- At least X lashing points must be used based on the formula below (L is the platform length given in mm).

| X = 1 + | L - (2 × 250mm) |

| 800mm |

- The distance between adjacent lashing points cannot exceed 700mm. In case of special situations (E.g. wheel well) max. 1200mm allowed.

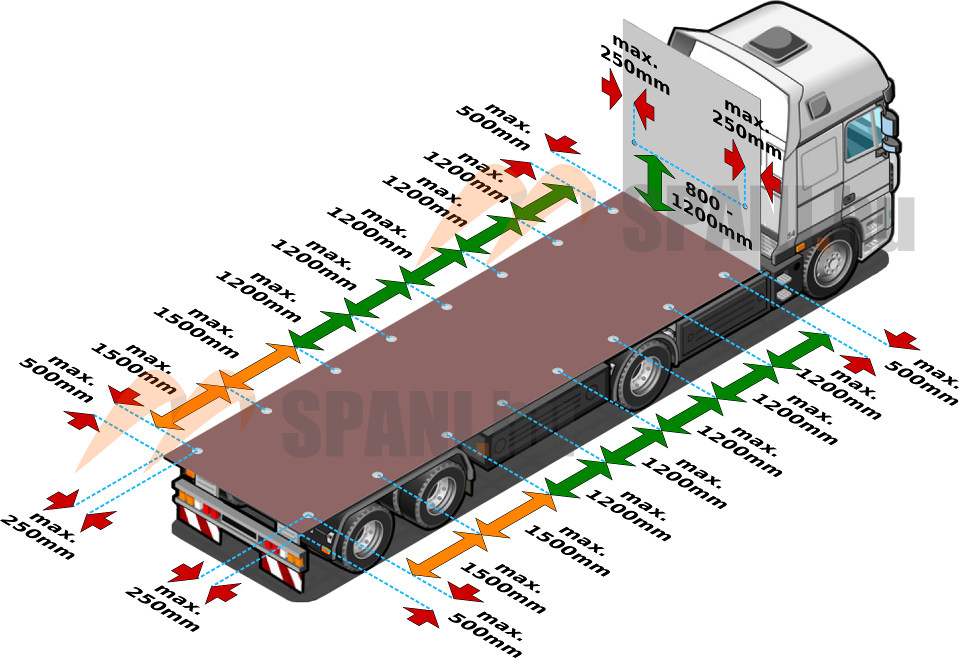

Lashing point placement (EN 12640, DIN 75410-1)

- Platforms not longer than 2200mm must have at least 4 lashing points (2 on each side).

- Platforms longer than 2200mm must have at least 6 lashing points (6 on each side).

- At least X lashing points must be used based on the formula below (P is the payload in daN, LC is lashing point capacity in daN).

| X = | 1,5 × P |

| LC |

- The distance between adjacent lashing points cannot exceed 1200mm. Above 3,5 tons maximum mass 1500mm distance can be used at the wheel wells.

- Lashing points must be placed within 500mm of the front part and the rear part of the platform.

- Distance from the sidewalls must be as small as possible and cannot be more than 250mm.

Above 3,5 tons maximum mass the headboards must be equipped with 1 pair of lashing points according to the rules below.

- The placement must be symmetric to the centerline.

- Height from the platform must be between 800-1200mm.

- Distance from the sidewalls must be as small as possible and cannot be more than 250mm.

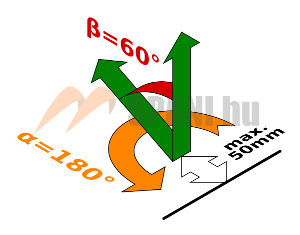

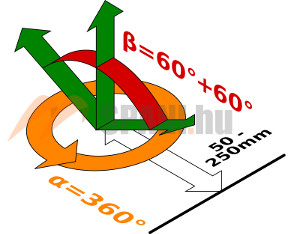

Angle of inclination (β) and angle of rotation (α)

The lashing point must grant the same lashing capacity to different directions. These directions are represented by the angle of rotation and inclination according to the figures below.

Lashing capacity and testing

Lashing capacity is verified by testing and certificate issuance. According to EN 12640 and ISO 27956 the lashing point must load testet with 125% of the (LC) for at least 3 minutes. The test is successful if there is no sign of deformation or damage afterwards.