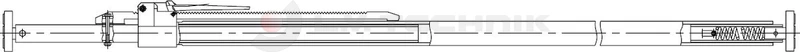

Cargo bar alu buffering 2350-2720mm 42mm

Code

LK8012

Price

Please sign in

Min. stroke (mm)

Max. stroke (mm)

Diameter (mm)

2350

2720

42

- 42mm thick with springs stroke length: 2350-2720mm

- with antislip cover on the fixing surfaces

- Capacity: 150daN

Material

anodized aluminium

Weight

4,8 kg

Stock

Lajosmizse

-

Szigetszentmiklós

-

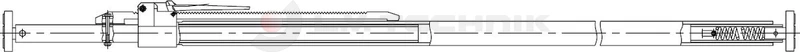

Cargo bar alu buffering 2350-2720mm 42mm Wistra

Code

LK8011

Price

Please sign in

Min. stroke (mm)

Max. stroke (mm)

Diameter (mm)

2350

2720

42

- 42mm thick with springs stroke length: 2350-2720mm

- the product hasDEKRAcertificate

- with antislip cover on the fixing surfaces

- Capacity: 150daN

Material

anodized aluminium

Weight

4,8 kg

Stock

Lajosmizse

in stock

Szigetszentmiklós

in stock

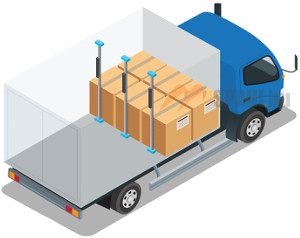

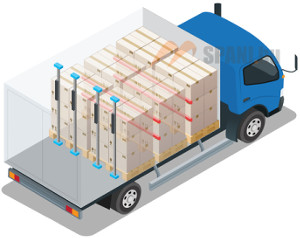

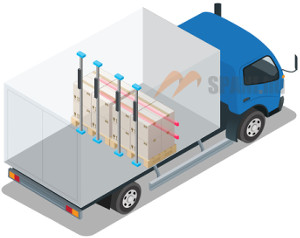

Load securing by blocking

In case of blocking load securing the load is placed tightly next to each other - typically the foremost load is lied against the headboard -, and the free surfaces are blocked with a proper cargo control device to prevent the whole cargo from sliding. These devices are mainly bars, beams or parting wall locks, but it can be done with lashing straps also.

- With a double hook made of 6mm round bars at both ends.