S-Line round shoring bar with rubber foot

Code

142138813G

Price

Please sign in

Min. stroke (mm)

Max. stroke (mm)

Diameter (mm)

2000

2600

42

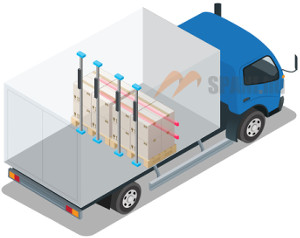

- 42mm aluminium cargo bar with spring and 2000-2600mm stroke

- anti-slip rubber foot

- ratchet tensioner for better fastening

- patented force display

- Blocking capacity: 130daN

- DEKRA certified

Material

anodized aluminium

Weight

4,9 kg

Stock

Lajosmizse

in stock

Szigetszentmiklós

in stock

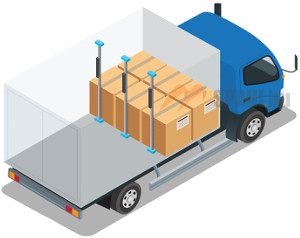

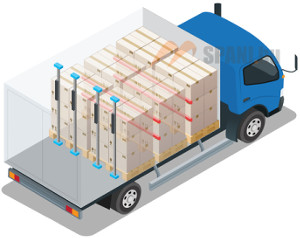

Load securing by blocking

In case of blocking load securing the load is placed tightly next to each other - typically the foremost load is lied against the headboard -, and the free surfaces are blocked with a proper cargo control device to prevent the whole cargo from sliding. These devices are mainly bars, beams or parting wall locks, but it can be done with lashing straps also.

- With a double hook made of 6mm round bars at both ends.